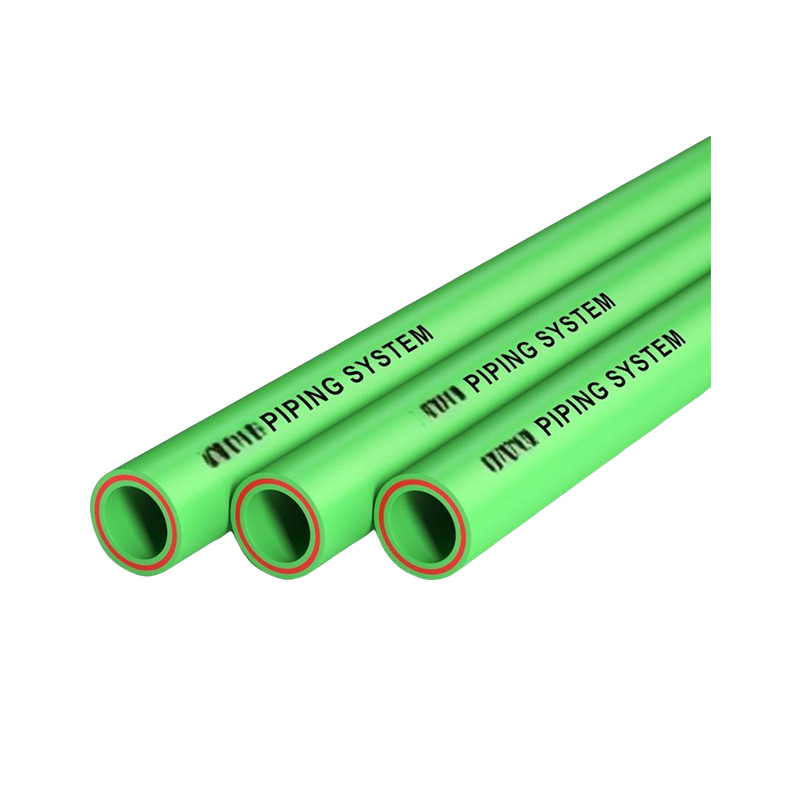

While PVC threaded penetration pipes do not completely surpass metal sleeves in fire resistance, their self-extinguishing properties after flame-retardant modification, excellent synergy with fire-stopping materials, and the low-smoke and low-toxicity cha

- +86-18607082539

- 1005890903@qq.com

- Jiaohu Entrepreneurship Base, Wuyang Town, Nanchang County, Nanchang City, Jiangxi Province